Gestión de Compras has extensive experience in the design, development and manufacture of extruded aluminium profiles.

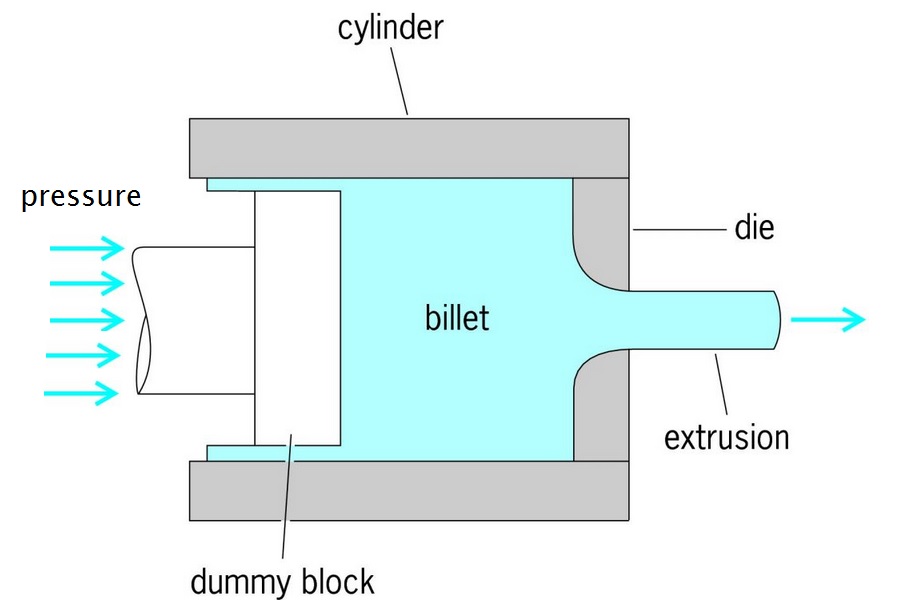

Process of extruded aluminium

Extrusion is a process of shaping a mass, bringing them out from an opening profiles for elaborate and complicated design. In the case of the aluminium extrusion, is carried out with alloys such as aluminium:

- 6063-T5

- 6063-T6

- 6061-T6

- 6005-T5

- etc.

Aluminium may be of first use, and also recycled.

Maintenance is very important in the process of extrusion products. For this reason, avoid storing it with chemical materials or wet materials.

Regulations

Our factories have the most demanding certifications for customers to ensure product quality as

- ISO 9001

- TS 16949

- ISO 14001