There are many questions about both steels. Which one should I use? What are its disadvantages? Is one stronger than the other? Which one will last the longest in good condition? What’s the difference between one and other? Purchasing Management will answer these and other questions throughout this article, Stainless steel VS Carbon steel.

First of all is to define each term. Stainless steel is mainly characterized, as its name suggests, by its resistance to rust. It is an alloy of iron, nickel, carbon and a minimum of 10.5% chromium. Depending on the type of stainless steel, it can contain other alloying elements, such as molybdenum, vanadium, sulfur, etc.

For its part, carbon steel is one of the great products of the sector, since it is known that historically 90% of the steel produced worldwide is carbon steel. Its composition is complicated, mainly made up of iron and carbon, but with other alloying elements such as silicon or manganese, sulfur, phosphorus, etc. These last two, along with others, are considered difficult impurities to extract from the final product. On the other hand, the greater the amount of carbon in the composition, the higher the tensile strength, but the index of cold brittleness will increase and the ductility and toughness of the product will decrease.

Depending on the amount of carbon contained in the composition, carbon steel can be classified into three types:

- Medium carbon level

- High carbon level (between 0.3% to 1.7% carbon)

- Ultra-high carbon level (1% to 2% carbon)

The most common is usually low carbon steels, due to their greater ductility, their manufacture is easier and their cost is lower.

Stainless steel VS Carbon steel

The main difference between these steels is due to the amount of chromium used in its composition. Chromium (Cr) is the chemical element that provides stainless steel with an inert layer of chromium oxide that achieves this resistance to corrosion.

Chromium in its pure state

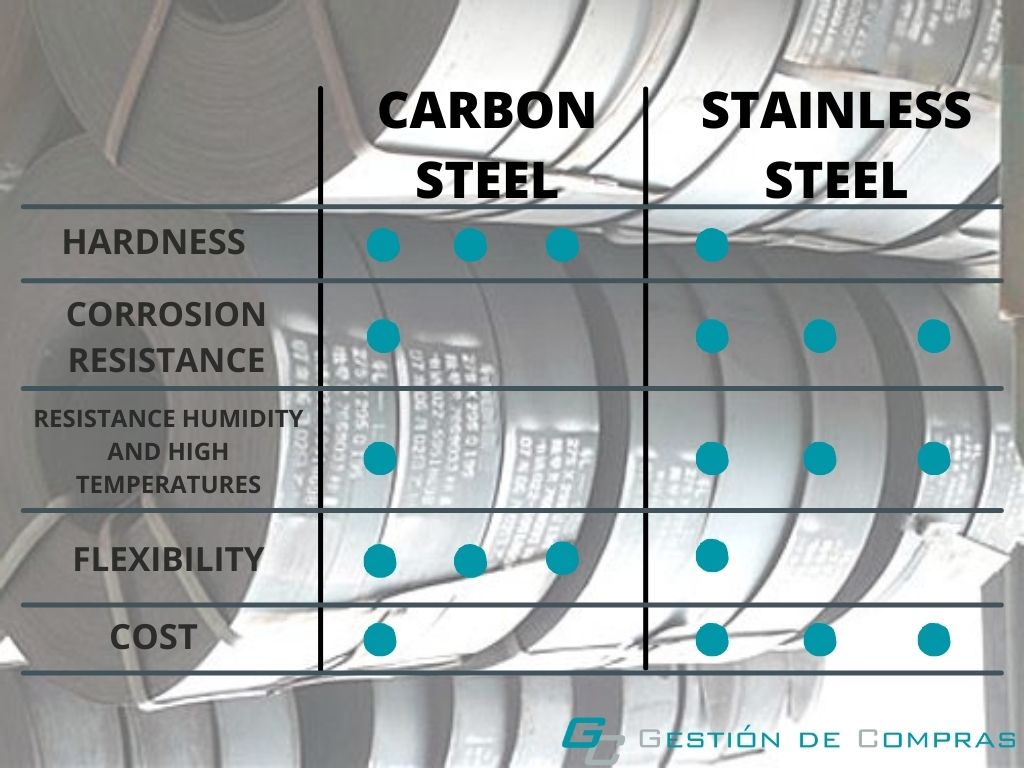

In addition, each of these steels has different qualities and characteristics, differentiating one from the other. The main disparities between stainless steel and carbon steel are: hardness, strengths, appearance, applications and price.

Stainless steel is softer than carbon steel, although it is also very hard. Regarding resistance, stainless steel also has greater resistance to humidity and lower temperatures, as well as oxidation; compared to carbon steel, which has greater flexibility and is ideal for dry environments.

On the other hand, steels also differ not only in their qualities, but also externally. Carbon steel is characterized by its opaque finish, while stainless steel is shiny, to a greater extent depending on the amount of chromium in its composition. In addition, stainless steel has a finish that does not require care or maintenance to maintain its original shape, unlike carbon steel.

Finally, another of its differences is the price. The value of stainless steel is higher compared to carbon steel, due to the chemical elements required to make it (manganese, chromium, nickel, etc.)

Applications

Depending on the sector in which we are going to use the material or the specific use that we give it, you must choose correctly which of the two steels is appropriate. From Gestión de Compras, we guide our clients in this choice particularly and depending on each case.

However, in a general way, stainless steel is ideal for consumer or visible products, such as in construction, automobiles, surgical tools and machinery. Carbon steel is often used in procedures where the steel is hidden from view.