We can classify into two main injection molds. Each one has its advantages, which largely depend on the planned volumes. Let’s take a closer look at which type may be best for your project. A single-cavity plastic injection mold is the most basic form of tooling and the most common. With this type of tooling, one production run produces one finished part.

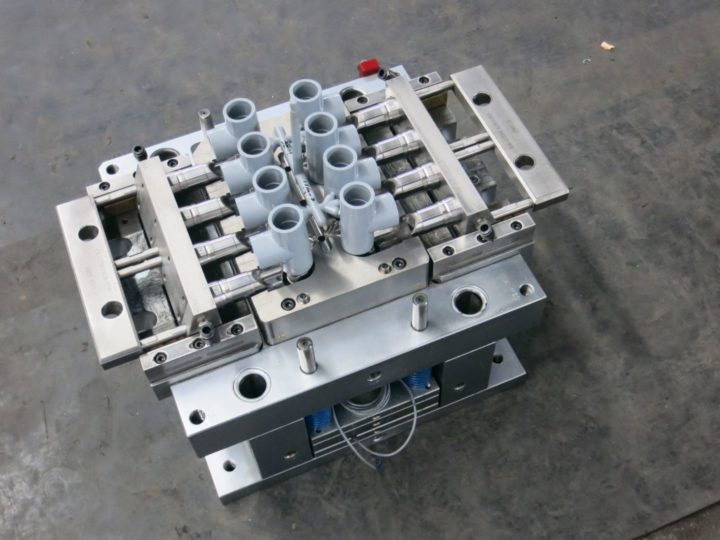

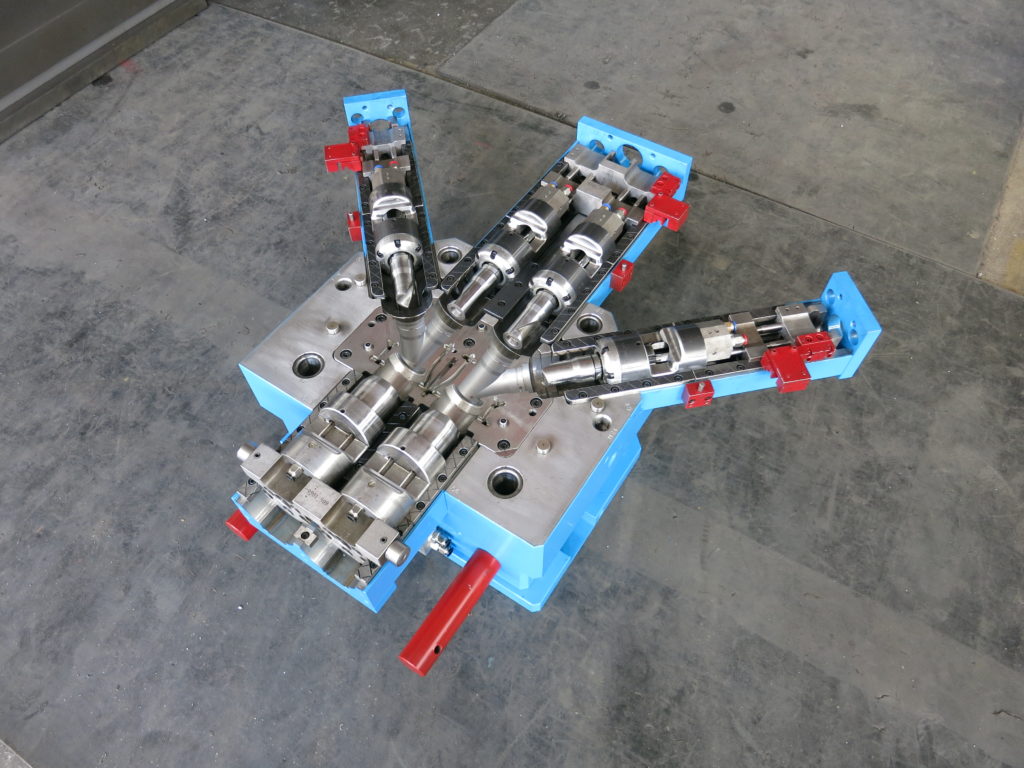

Multi-cavity or multi-cavity molds have at least two cavities and two cores, with a practical limit of hundreds of small cores and cavities. All shapes are the same and are produced in balanced pairs. Because there are so many cavities, a production run can produce dozens or even hundreds of finished parts, depending on the capacity of the molding machine.

Gestión de Compras has a wide experience designing and producing plastic injection molds, both single and multi-cavity. Do not hesitate to share with us your project to develop your molds and parts with us.

Let’s take a closer look at the characteristics of each one:

SINGLE CAVITY MOLDS

There are many good reasons to use single-cavity plastic injection molding.

Advantages of single-cavity tooling

- Faster manufacturing

- Less expensive tooling option for basic shapes

- Easy to control processing parameters, so molding conditions tend to be more stable and predictable

- More suitable for low volumes of finished parts

- Drawbacks of single cavity tooling

- Slower production times

- Higher cost per finished part

MULTI-CAVITY MOLDS

Multi-cavity tooling is an excellent solution for the right project. Here are some of its advantages.

Advantages of using multi-cavity tooling

- More parts per cycle, making them suitable for larger orders

- Lower cost per part than single-cavity tooling

- Better color consistency between parts

Disadvantages of using multi-cavity tooling

- Takes significantly more time to design and manufacture multi-cavity tooling, and is more expensive.

- MoldFlow analysis must be performed to predict, and control, the additional stresses and constraints that the resin encounters inside the tool.

- They use more complex gating and channel systems, as well as cooling channels.

- It may be necessary to reorient the part within the tool to allow for different gate locations. This, in turn, will affect ejector marks, gate witnesses and other minor defects in the finished part.

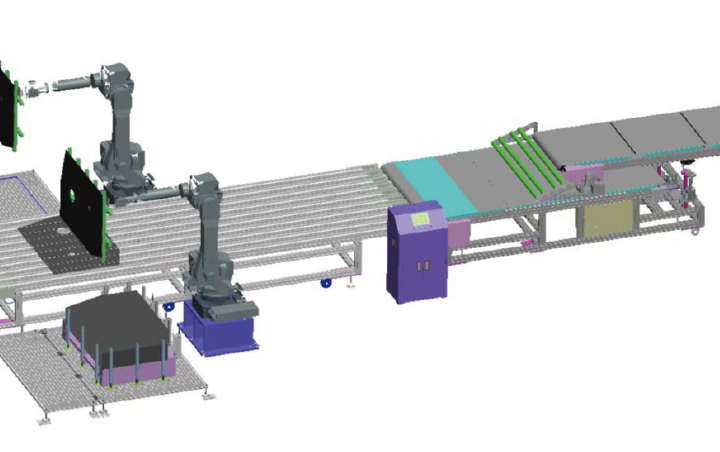

CYCLE TIMES AND SINGLE AND MULTI-CAVITY TOOLING

Production cycle time is a critical variable that developers must be able to predict and control. Cycle time directly influences the volume of parts that can be produced – and therefore shipped – in a given time frame, as well as affecting the cost per part.

When order volumes increase, it is advantageous to reduce cycle times to a minimum. This is less of an issue with smaller orders.

But to achieve the fastest possible cycle times, it may be necessary to make an initial investment in higher quality tool steels, multi-cavity tools and tool surface coatings that extend tool life while improving performance.

Again, this additional expense is only justified if the anticipated volume is high enough to recover the cost over time.