Description

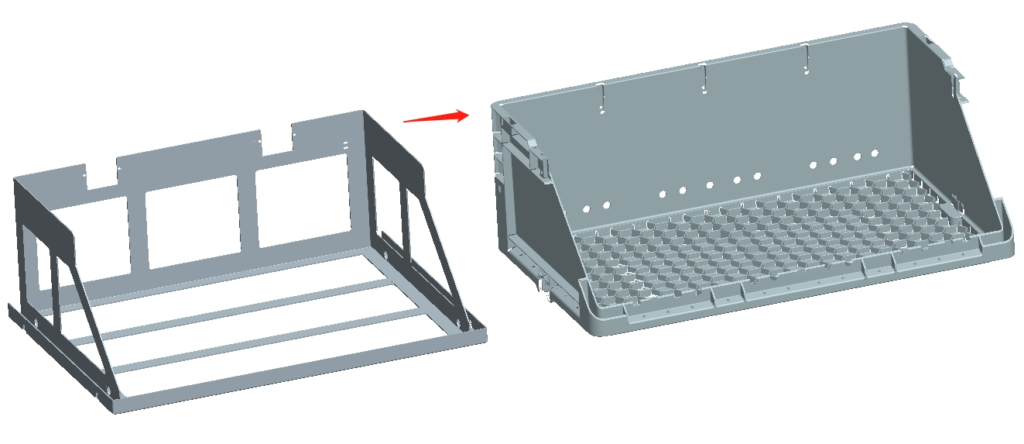

Gestión de Compras received a request from a customer who has several shelf designs in sheet metal.

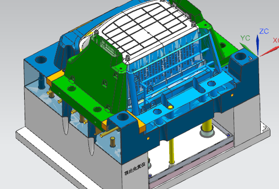

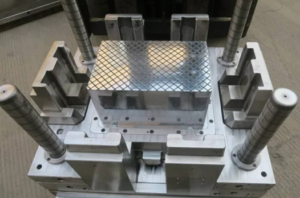

As in many other cases, this customer needs to update and improve the existing metal designs of these parts in order to convert them to plastic, validate prototypes and develop plastic injection molds for mass production. For the customer, it is key that the parts are able to withstand high weights.