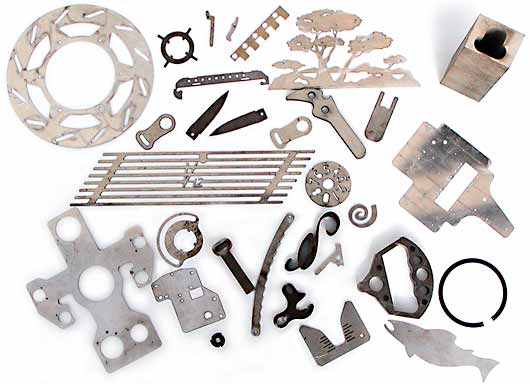

Gestión de Compras have means of production available for carrying out the processes of stamping, cutting, drawing, folding, punching, etc. We also supply laminated products made of galvanized steel, stainless steel, copper and other materials.

Process

The sheet metal is a flat material, which presents various thicknesses. The main feature is the combination of a very small thickness and a height and width much larger. Parts made from these sheets are made of materials such as carbon steel, aluminium, stainless steels, and other materials such as copper or titanium. These parts are intended for industrial use in the automotive, packaging or processing appliances. His surface has high quality finishes.

Products

The products made from these materials are obtained by different processes. Some of them are as follows:

- The cold sheet metal forming, for thin sheets with low carbon levels.

- Hot sheet metal forming, for thicker sheets and high elasticity steels.

- There are also other techniques, like punching, laser cutting, sheet metal bending, drawing, deep drawing, etc.

The tools often have a high cost and high complexity. One type of them are called dies. These dies are tools for cutting and shaping sheet plates. These processes are quite clean, without chip removal. Other tools required are punch, rollers, folding machines, etc.

The main advantage of this process is the high productivity. It is a profitable process if client needs a large number of parts. But if few parts are required, sheet metal forming is not a viable option.