In Gestión de Compras we work with suppliers that use techniques and equipment on the-state-of-the-art to produce parts made by EDM.

Process of EDM

EDM or Electric Discharge Machining is a machining process, which consist on remove material from work-piece by electric discharges. The electrode is a very important part of the process. It is a good conductor. It is coated with graphite to improve wear resistance. The size and shape of this piece can be quite varied.

During the process, it generates an electric arc between the work-piece and the electrode. This arc reaches a high temperature that produce a crater on the work-piece to develop the final component.

Types of EDM

To carry out this process usually the two parts, electrode and work-piece, are immersed in a dielectric (electrically nonconducting) liquid which is circulated to flush away debris and permit a higher control of machining temperature.

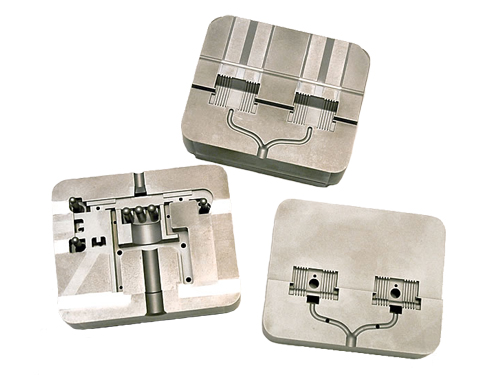

EDM can be carried out using two different types of processes. Sinker EDM or Wire EDM.

Sinker EDM:

Electrode and work-piece are connected to power supply. Between electrode and work-piece there is an electrical potential. Sparks erode material.

Wire EDM:

In this type of process is used a thin single-strand metal wire. It can cut a very complicated shapes. Thin single-strand metal wire is normally brass.

EDM advantages

- A good results in surface appearance.

- Complex design parts easier achieved.

- EDM allows to work with small work-piecethat othertools will damagethework-piece.

- Extremely hard material to very close tolerances.

EDM disadvantages

- Low amount of material removal.

- Easily and quickly wear tool.

- Large consumption of energy and time.

- It only works with conductive materials.

Tolerances

By this operation is possible obtain lineal tolerances of about a few micrometres working with correct wire size, machining speed, etc.

Wired electric discharge machining permit obtain cuts with parallels walls, unlike those cut by laser or water jet.

Standard and certificates

Our companies have world reference quality and safety standards such as:

- ISO 9001

- ISO 14001

- TS 16949

- ISO 11090-1

- ISO 14137

- OHSAS 18001

- ISO 28881