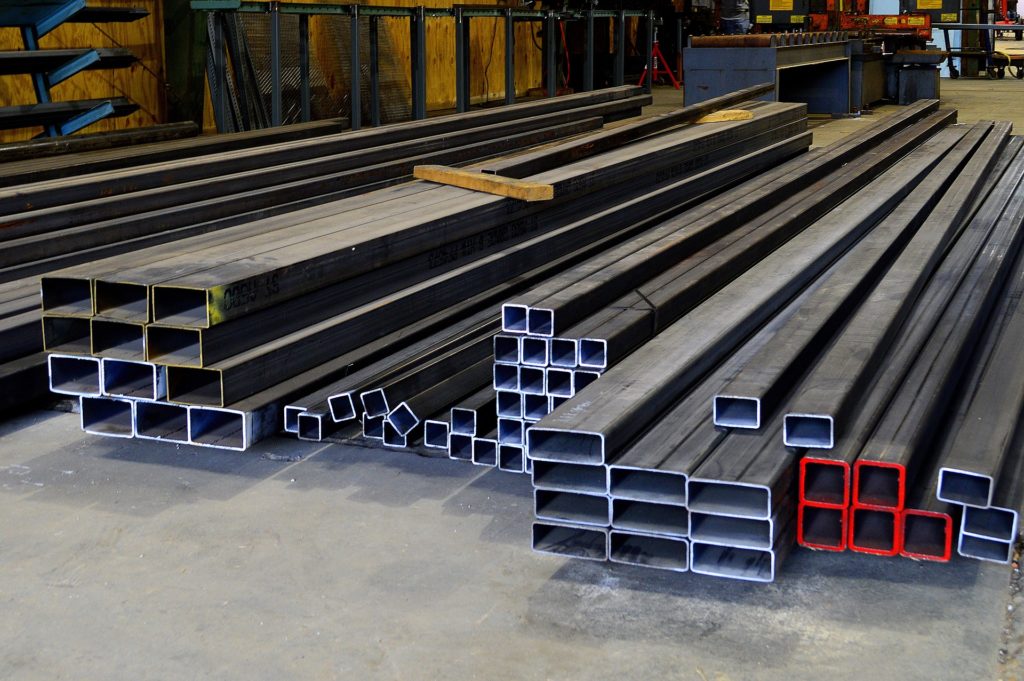

It is essential to understand the differences between rolled steel grades when choosing them for your project. That prior knowledge will help you save costs and time, while avoiding additional processing. This article describes the difference between hot-rolled and cold-rolled steel, including their advantages, limitations and applications.

Hot rolled steel

Rolling refers to the specific way in which the steel material is produced. Hot rolled steel refers to steel produced with extreme heat treatment. That is, production occurs at extreme temperatures, above 926° Celsius. After rolling the steel in the rolling mill to the desired shape, it is allowed to cool.

Properties of hot-rolled steel

Properties of hot-rolled steel

- Flaky surface – cooling at high temperatures leaves debris on the surface of the steel that gives it a flaky appearance.

- Slight distortions – cooling also produces slightly trapezoidal shapes without perfect angles.

- Slightly rounded corners and edges – is the result of shrinkage and less precision in finishing.

Advantages

- Lower cost: Hot-rolled steel is much less expensive to process than cold-rolled steel.

- Little or no internal stress: The cooling of hot-rolled steel occurs at room temperature, which makes it essentially standardized. This means that internal stresses due to the hardening or cooling processes are minimal or non-existent.

- Easier to work with: Because the hot rolling process is carried out at extremely high temperatures, the resulting steel is easier to shape and form. The most common shapes of hot rolled steel are, for example, UB, UC, RHS, SHS, flats, etc.

- Applications: It is ideal for applications where tolerance is not the priority.

Disadvantages

- Dimensional defects due to expansion during heating and shrinkage/deformation during cooling.

- Often presents a rough texture on the surface that needs to be removed or punctured prior to any finishing process.

- Slight distortions.

Cold-rolled steel

Basically, cold-rolled steel is hot-rolled steel that has undergone a transformation process. As mentioned above, rolling encompasses the full range of processes involved in steel forming, including turning, grinding and polishing. The other operations modify an existing hot-rolled steel into a more refined product. The term “cold rolled” is essentially applied to steels that have undergone compression.

Properties of cold rolled steel

- Smooth surfaces tend to have an oily feel

- Surface has better finishing qualities and tighter tolerances

- Square bars have well-defined edges

- Tubes tend to have better straightness and concentric uniformity

Advantages

- Better surface properties: Parts made from cold-rolled steel tend to have smooth, bright surfaces, free of scale and rust. This makes them useful when aesthetics are essential.

- Higher strength: They are usually stronger and harder (up to 20% harder) than hot-rolled steel. This makes them useful for high stress applications.

- Greater precision: Since cold-rolled steel does not shrink during forming, it allows for more precise parts with consistent and accurate shapes.

- Various surface finishes: A wide range of surface finishes are possible.

Disadvantages

- More expensive due to the additional processing involved.

- Internal stresses occur in the material due to the additional processing, leading to unpredictable warping in some cases.

- Fewer shapes are available, e.g. sheets and boxed sections.

Should I choose hot-rolled or cold-rolled steel?

The choice will depend on several factors. One of the main factors to consider when deciding between cold-rolled and hot-rolled steel is the applications of the final product. Hot-rolled steel is more suitable for large structural components that do not have tight tolerances or aesthetic requirements.

However, cold-rolled steel will be the better choice if you need smaller parts that require durable and more precise grades. Cold-rolled steel is also stronger and harder than hot-rolled steel. Therefore, it is more suitable for components manufactured for use under high stress conditions. If budget is an issue, you should opt for hot-rolled steel because it is cheaper than cold-rolled.