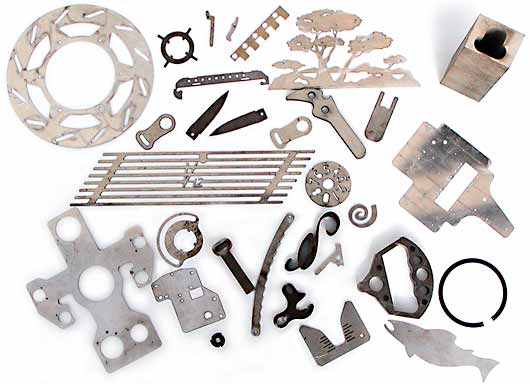

Gestión de Compras has means of production available to get a wide range of products by water jet cutting.

Process of Water cut

Water jet cutting is a process that uses a high pressure and speed jet of water to cut a wide variety of materials. According to the material to be cut there are two principal types: pure waterjet that uses only water and abrasivejet which use a mixture of water and abrasive to cut hard materials.

The equipment required for this process consists of a pool of water, nozzle, cooling center, warehouses for abrasives, decalcification, and a purifier of abrasives.

The two most important elements in the process are water cutting nozzle and pressure. Water mixed with the abrasive component necessary exits a nozzle at a pressure very high. The shape of the nozzle directly affects the accuracy and quality of the jet. The water pressure must be strong enough to produce the cut.

This process has got many advantages such as:

- High quality cutting.

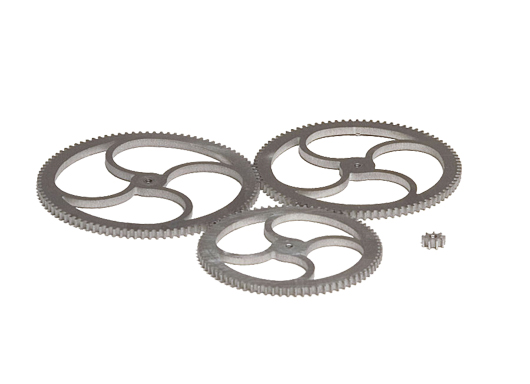

- Versatility, the same machine can cut a wide range of materials.

- Enviromentally friendly.

- Cold cutting: no heat-affected zones.

- Multi-axis cutting.

- Stress-free cutting.

- No produce dust or contaminant gases.

This operation hasn’t got notable disadvantages

Tolerances

Water jet cutting operation offer a good dimensional tolerance and a very high edge quality. Both depends of cut speed and thickness of material. The lower the cut speed and thickness, the greater accuracy and quality.

Cut edge quality for this process is defined by numbers Q1 to Q5. Being Q1 fastest cut with a low edge quality and Q5 have a high quality (usually no secondary finishing is required) but is slower and more expensive.

Standard and certificates

We have the means to ensure our products comply the general regulation and the specific certificated regulations in manufacturing products that requires them.

- ISO 9001, TS 16949 and ISO 14001.

- ISO 12100 machinery safety

- ISO 8062, ISO 286-2, DIN 2768,DIN 1697, etc.