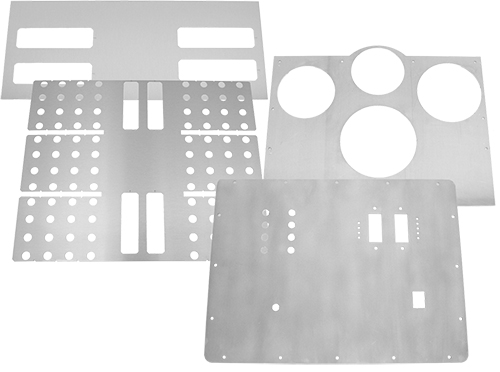

Gestión de Compras are supplied by factories on the-state-of-art of laser cutting. They are able to work with any material and method of laser cutting to offer ours costumers the most competitive products.

Process of laser cutting

The laser cutting process uses a laser light, which has a very high energy density, to cut the material. Materials employed in this method are sheet of carbon steel, aluminium, stainless steel, copper, magnesium, titanium… In areas covered by this light sheet material melts. Material is removed by applying a pressurized gas, usually argon, oxygen or nitrogen.

Laser cutting is a high accuracy operation helped by a computer numerical control system (CNC). It’s especially recommended to cut low thickness sheet (under 2 mm) but it is capable to cut up to 1 inch (25 mm).

Laser cutting has several advantages

- It allows creating a silhouette adjusted figures

- This is an automated robotized procedure.

- During laser cutting, little material is lost

Moreover, a stylus or laser head itself can carry out different cuts of different sizes and shapes.

Among the disadvantages,

- Highlights the large investment needed to acquire the necessary equipment for this process

- We must also take into account the properties of the sheet material with which it will work. If it is a material with heat conducting capacity high, not work well as it will be very difficult to apply the cut.

Tolerances

Dimensional allowance for this process depends of thickness and material of the sheet. If greater accuracy is not required we work usually within 0.05 mm for sheet thickness up to 2mm.

Standard and certificates

Our companies have world reference quality and safety standards such as:

- ISO 9001

- ISO 14001

- TS 16949

- ISO 9013

- EN 60825

- OHSAS 18001