Gestión de Compras have the means to design, develop and manufacture gears, on a wide variety of different manufacture processes and materials.

Product

A gear is a toothed part to transmit power or motion from a shaft to another or to change speed or direction.

This elements are defined by several parameters, such as number of teeth, pitch, modulus, pressure angle, angle of action, etc.

Exist a great variety of gears, depending of the tooth shape and function its possible make the following classification:

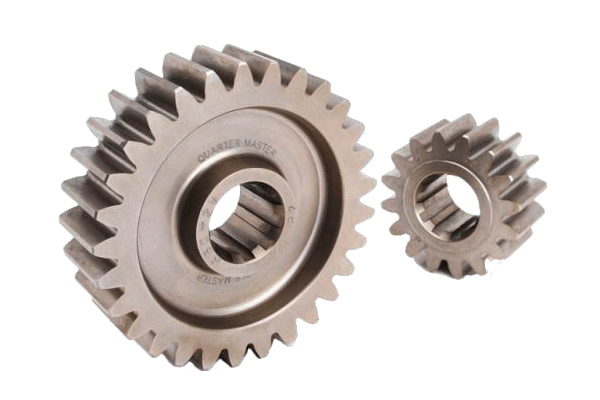

Spur gear

also called straight gear, this is a cylindrical shaped gear in which the teeth are parallel to the axis. This type are the most common type used and the easiest to manufacture.

Helical gear

This is a cylindrical shaped gear with helicoid teeth. Helical gears are widely used in industry because can bear more load and higher speed than spur gears, and work more quietly. The principal disadvantage is the axial thrust force the helix form causes. This type of gear could be mounted in parallel axes or in crossed axes.

Double helical gear

Also known as Herringbone gears, this is a gear with both left-hand and right-hand helical teeth. The double helical form balances the inherent thrust forces.

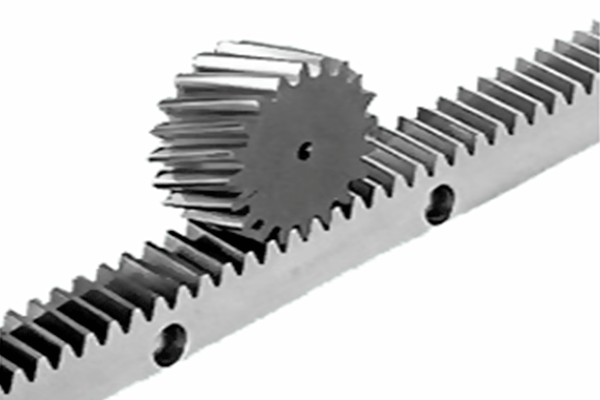

Spur rack

Rack and pinion system is a linear shaped gear which can mesh with a spur gear with any number of teeth. The spur rack is a portion of a spur gear with a supposed infinite radius. Torque can be converted to linear force when the pinion turns.

Helical rack

this set as the same characteristic that spur rack and pinion, but with the difference of linear shaped gear meshes with a helical gear. Again, it can be regarded as a portion of a helical gear with infinite radius.

Straight bevel gear

This is a gear in which the teeth have tapered conical elements that have the same direction as the pitch cone base line. Their imaginary vertices must occupy the same point. Their shaft axes also intersect at this point, forming an angle zero or 180 degrees both non included. Bevel gears with equal numbers of teeth and shaft axes at 90 degrees (such as we can see on right picture) are called mitre gears.

Spiral bevel gear

This type of gear consist on a bevel gear with a helical angle of spiral teeth. Spiral bevel gears have the same advantages and disadvantages relative to their straight-cut cousins as helical gears do to spur gears. It is much more complex to manufacture, but offers a higher strength and lower noise.

Hypoid

This is a special development of spiral bevel gears who permit drive bevel gears with nonintersecting axis. The pitch surfaces appear conical but, to compensate for the offset shaft, are in fact hyperboloids of revolution. Usually hypoid gears operate with shafts at 90 degrees.

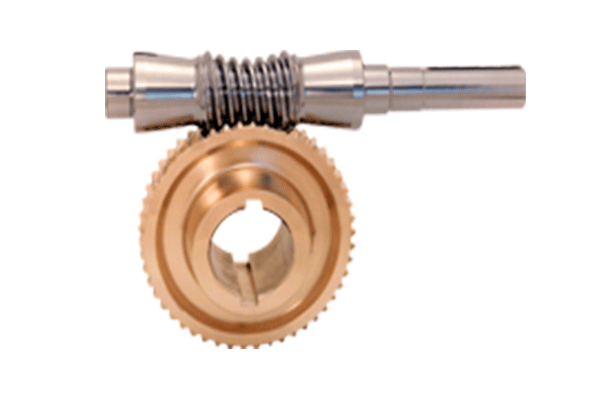

Worm and worm gear

Worm set is the name for a meshed worm and worm gear. The worm resembles a screw thread; and the mating worm gear a helical gear. Worm set offer a simple and compact way to achieve a high torque and low speed gear ratio. However, transmission efficiency is very poor due to a great amount of sliding as the worm tooth engages with its mating worm gear tooth and forces rotation by pushing and sliding. With proper choices of materials and lubrication, wear can be contained and noise is reduced.

Double Enveloping Worm Gear

Also called cone drive, this special type of worm set uses a special worm shape in that it par¬tially envelops the worm gear as viewed in the direction of the worm gear axis. Its big advantage permit the higher power transmission than conventional worms.

Face gear

Also known as crown gear, is a pseudo bevel gear that is limited to 90º intersecting axes. The face gear is a circular disc with a ring of teeth cut in its side face; hence the name face gear. Tooth elements are tapered towards its center. The mate is an ordinary spur gear. It offers no advantages over the standard bevel gear, except that it can be fabricated on an ordinary shaper gear generating machine.

Standard and certificates

We ensure that our suppliers are holders of the most demanded certificates, such as:

- ISO 9001

- ISO 14001

- OHSAS 18001

- TS 16949

- DIN 3960, DIN 3961, DIN 3964, DIN 3967, DIN 3977 y DIN 868