In Gestión de Compras we design, develop and manufacture plastic injection molds for multiple sectors.

Injection molding process

Injection molds are ideal for producing large volumes of plastic parts, due to the possibility of making multi-cavity injection molds. Some of the advantages of injection molding are high tolerances, repeatability, fast cycle times, ability to produce over 100,000 parts with proper maintenance, a wide range of materials, low labor, minimal waste production and little need for finishing operations after molding.

We have 20 years of experience developing custom molds according to our customers’ needs and requirements using conventional machining (CNC) and electrical discharge machining (EDM) methods. Our hands-on experience in mold design and manufacturing can help you solve various functional, aesthetic and cost challenges before they become problems and costs.

Our team of moldmakers, engineers and designers has considerable experience including single cavity, multi-cavity, hot runner, overmold, 2k, etc. tooling.

Among our qualities we highlight the development of MoldFlow, this software allows us to provide detailed information about the flow, cooling and distortion of the components. As well as Automation through robots and automation systems, in charge of moving the parts, storing them, assembly with metal inserts, etc.

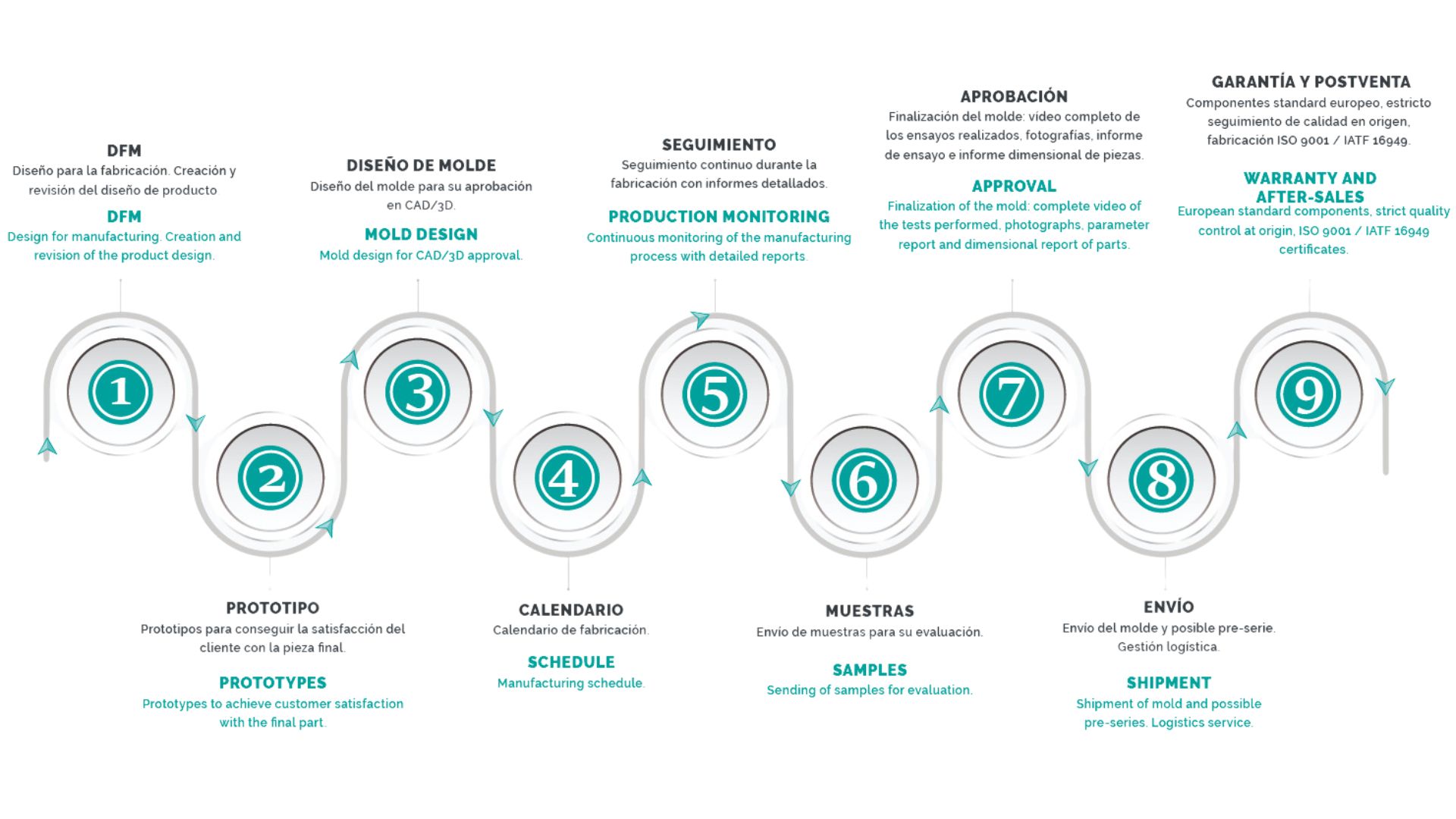

Our workflow

- DFM: Design for Manufacture. Creation and review of product design.

- PROTOTYPING to achieve customer satisfaction with the final part.

- MOLD DESIGN for CAD/3D approval.

- MANUFACTURING SCHEDULE.

- Continuous MONITORING during manufacturing with detailed reports.

- SAMPLES: Sending samples for evaluation.

- APPROVAL. Finalization of the mold: complete video of the tests carried out, photographs, test report and dimensional report of parts.

- SHIPMENT of the mold and possible pre-series. Logistics management.

- GUARANTEE AND AFTER SALES: European standard components, strict quality control at origin, ISO 9001 / IATF 16949 manufacturing.

Tolerances

Dimensional tolerances in mold manufacturing depend mainly on the method used to produce the mold. Conventional machining processes have typical tolerances of just under a tenth of a mm, while the EDM method is capable of better tolerances, closer to hundredths of a mm.

Regulations and certificates

We have the means to ensure that our products comply with general regulations and more specific certification regulations in manufacturing.

- ISO 9001

- ISO 14001

- IATF 16949:2016

- TS 16949, UNE-EN ISO 13485, …

- OHSAS 18001.